This weekend I set the inboard and outboard sections of the left wing plug up on the table, and executed the structural splice between them. I did the splice exactly as on the right wing plug, except for the alignment. Instead of aligning the sections so that the carbon stiffeners formed a straight line (or, more correctly, occupied the same plane), I aligned the sections according to a map of the right wing plug I'd made the previous weekend. That helps make sure that both wings have the same planform, and that the finished aircraft will be symmetrical.

I've probably mentioned this before, but early in the HP-24 development I floated the idea of having a slight asymmetry between the right and left wings. What I proposed was to have one wing mounted on the fuselage slightly further forward (about 1.4") than the other wing. This would have allowed me to align both wing spars along the plane of maximum depth in each wing, and would have made it slightly easier to develop the wing internals. Well, the idea seemed to give everybody the heebie-jeebies. Nobody could really find anything wrong with the idea, but everybody felt it was not right. And, frankly, I had to agree with the majority on this one. So now I'm doing what I can to make sure that the ship is at least symmetrical on the outside. The wings can't be symmetrical on the inside, since the spar stub overlap requires one spar to be further forward than the other. But you can't see that unless you're putting the thing together.

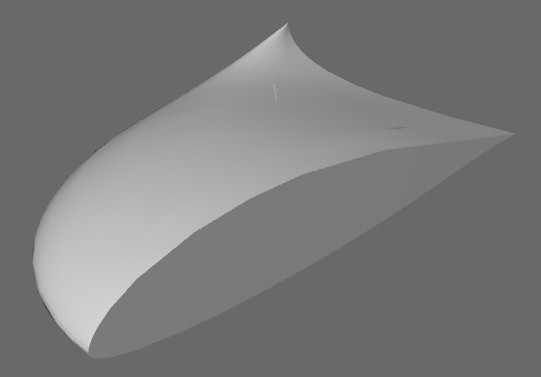

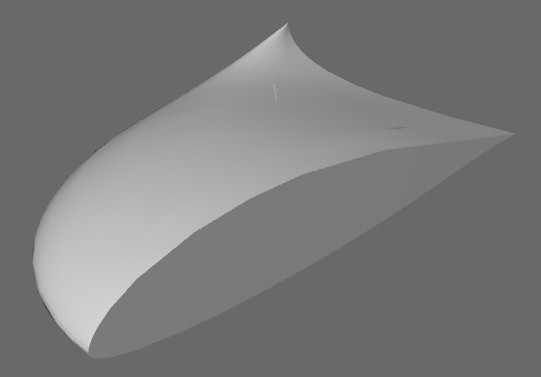

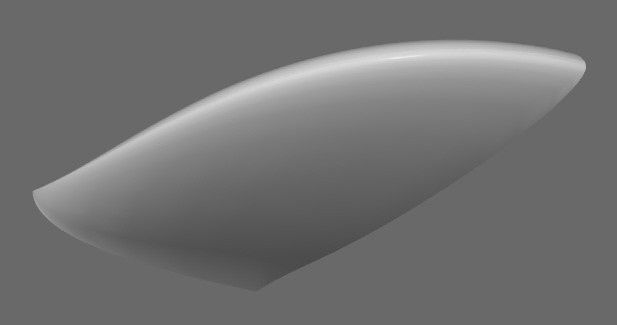

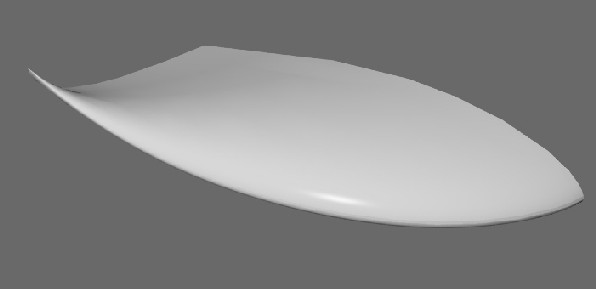

Last week I also received from Brad Hill the .igs files and some jpeg views of the "default wingtips" that will go on the wing plugs for molding. These are the wingtips you get by default if you don't order winglets. Brad did the 3D design of these tips according to a couple of sketches I sent him, and I think that they turned out very well. Unlike the horizontal stabilizer tips, which took me weeks to carve, sand, fill, fit, and blend, my plan is to have these tips CNC milled out of high-density tooling foam according to the .igs files. That will be a bunch more pricy than hand-carving them, but will save me a ton of shop time.

Here are some pictures of the tips:

This weekend I also got some work done on my HP-18, filling and painting the stabilizers. It's not going very well, and I've become somewhat resigned to doing a just-good-enough job. They'll be white and sorta shiny, but I hope nobody looks at them too closely or critically.

Next weekend, I'll be at Air Sailing's annual Spring Cleaning work party. The weekend after that, I figure to do the skin scarfs for the left wing plug joint, and then maybe get started with the moderately heinous job of sanding and filling the surfaces.

page updated 19 April 2004 all text and graphics copyright (c) 2004 HP Aircraft, LLC