Not much visible progress to report, but things are getting done in the background. We (Doug Gray and I) did go retrieve the horizontal tail molds from Tehachapi on Saturday 26 March; that trip went OK. We made our usual 4 am start, got to Tehachapi by 10 am, chatted with Harald, loaded the molds, and were in Murphys by sundown. That night we dropped the molds off at the Arnold shop, and called it a weekend.

On Easter Sunday the kids and I and Doug went to explore an unfamiliar Table Mountain rock climbing site. We switchbacked onto the top of Table Mountain and walked across it's broad, flat top to the descent trail for the climbing site known as The Far Side. It was resplendant with wildflowers on the top of Table Mountain; there were California poppies, Lupine, sea foam flowers, and many others I couldn't identify.

For the last couple of weeks I've been working on the plugs for the landing gear well boxes in a friend's garage, and that work is going pretty good though I haven't pictures to show for it. Also, in the last week or so Brad Hill has been making the composite gudgeons that will support the elevators and ailerons. The gudgeons get embedded in the lower wing skins and upper horizontal stab skins, and support the control surfaces by their embedded pintles.

Brad Hill and Doug Gray are scheduled to spend about a week solid in the shop between 22 April and 29 April; they'll do a bunch of work on fuselage tooling and etceteration. We don't have a well-defined to-do list, but we'll refine that as we approach those dates. There's surely plenty to do!

At the end of the week, I might be sending Brad back to Seattle with the wing plugs so that he can work on them in his shop in parallel with what I'm doing down here. We'd probably be sending him up there with the HP-18 trailer.

Unfortunately, I've no pictures of the gear well boxes in development, but here's a bunch of other progress pictures:

Here's my guidance sketch for the process of making the gudgeons.

Here's the strip of gudgeon material that Brad made using the materials that I had McMaster-Carr send him:

Here's a single gudgeon parted off to 3/4" width. My intent is to test it's stiffness in terms of deflection per unit load, and slice it thinner and thinner until it's just stiff enough. My bet is that it will still have adequate stiffness at about 1/2", and that I'll be using 5/8" width in practice.

A close-up perspective on the gudgeon, showing the 5/16" OD, 3/16"ID flanged Oilite bushing that gets glued into the gudgeon.

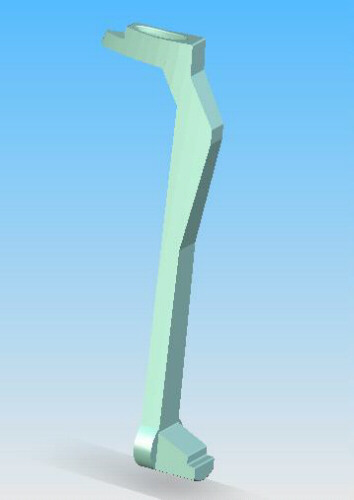

Here's a view of the vertical fin spar as Brad modeled it from my sketches. You can see that it's a pretty complicated part and does quite a lot of stuff. It serves as fin spar shear web (the carbon spar caps bond between it and the fin skin), upper and lower rudder hinge support, fin tip rib, and horizontal stab mounting platform. Brad models this stuff up in SolidWorks and Rhino, and then passes them off to me using the SolidWorks eDrawings feature. In eDrawings, I can rotate the model, measure parts of it, make parts disappear or go transparent, and add comments. And if we had six or seven digit $ to throw at this thing, we could take those models to the CNC shop and have them do the finished plugs or molds. But we're not, so mostly we use these models to guide us as we make the plugs by hand using Masonite and Bondo. If it's stupid but it works, it ain't stupid!

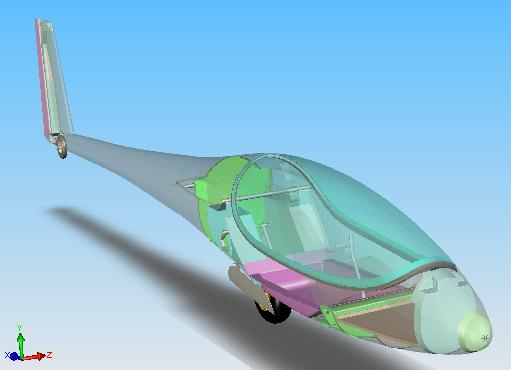

Here's a screen capture of one of the fuselage master drawings that Brad is using to fit everything together. You can see that it includes most of the important fuselage parts. A word of warning: there are some things in that drawing that are relatively speculative in nature; so don't make plans on what you see there.

Our long-term plan is to use things like eDrawings to make a fully-interactive computer-based construction guide that lets you view any part from any angle, and study its relationship with the assembly as a whole.

page updated 7 April 2005 all text and graphics copyright (c) 2005 HP Aircraft, LLC